For some strange reason – well, a couple of strange reasons, actually – I have a lot of feathers, and limiting myself to gluing them to things is kind of, well, limiting. Especially if I want to make dangly earrings, or necklaces, or or things, with them.

Wire wrapping seemed like the easiest way to make dangly things with them. I can’t recall if I found any examples online before I got started (my first page of Google hits now doesn’t turn up any particularly good tutorials), so let’s just say I made it up as I went along.

I have a lovely photoset at Flickr, with instructions, or you can read it all right here. (One of these days, I may also make an Instructable, but when I started one a week or two ago, the interface was so aggravating that I gave up.)

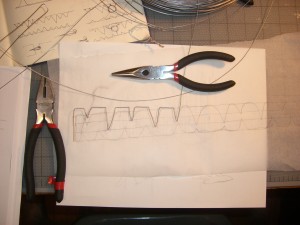

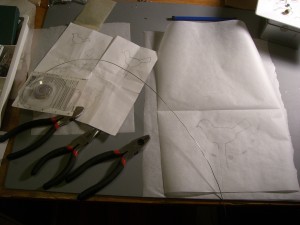

First, you need the following tools and materials:

- round-nose pliers*

- flat nose pliers*

- wire cutters

- feathers

- very thin wire (I used 26 gauge)

I tried two different methods. The first starts by forming a loop (with one short end and one long end) in the wire, to hang the feather from, and then wrapping wire down the shaft of the feather, trapping the short end of the wire against the feather shaft. The second starts by wrapping wire UP the shaft of the feather, again trapping wire against the shaft, then forming the hanging loop, and finishing by wrapping the remaining wire back down the shaft. I like the first method better, but both seem to create a pretty firm connection between the wire and the feather, though I didn’t try REALLY REALLY HARD to pull the feathers free.

So. On to the wrapping:

Because this was a tiny feather (OMG do not use a tiny feather for your first try) I wanted to have almost as much straight wire held against the feather as there was bare feather shaft. It seemed like it would be the strongest way to wire the feather, and aesthetically appealing.

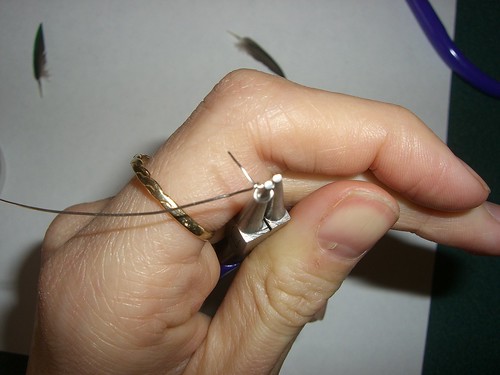

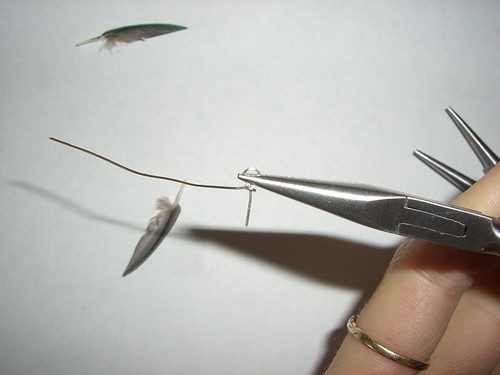

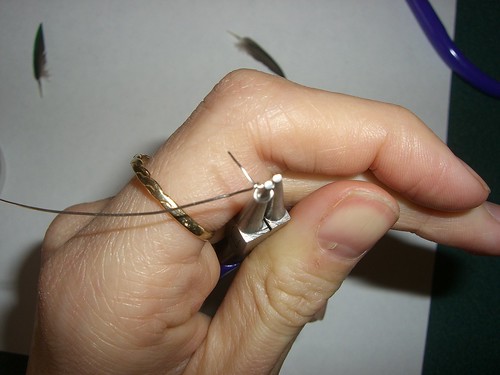

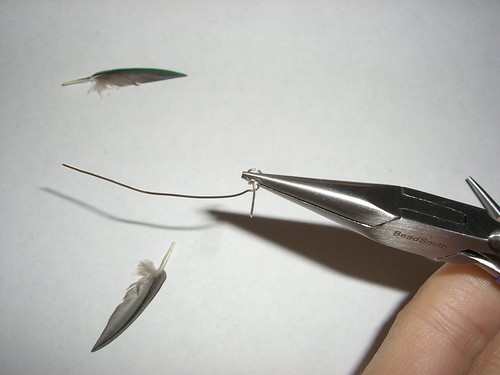

I grabbed the wire with the round-nose pliers where I wanted the straight part to end, and the loop (to hang the feather from) to begin.

I wrapped the long end (still attached to the spool, because I like making life more complicated) around the pliers to complete the loop.

Then I bent the long end back around the short straight end, to start the wrapping of wire around the straight wire plus - in a moment - the feather.

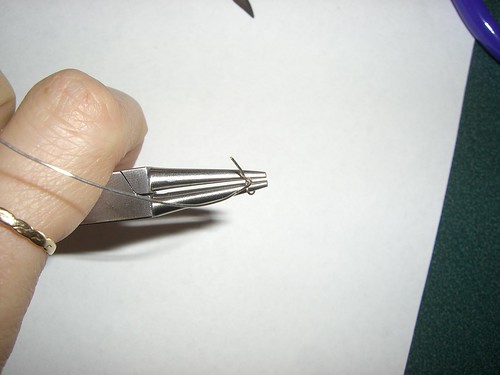

Another view of the loop

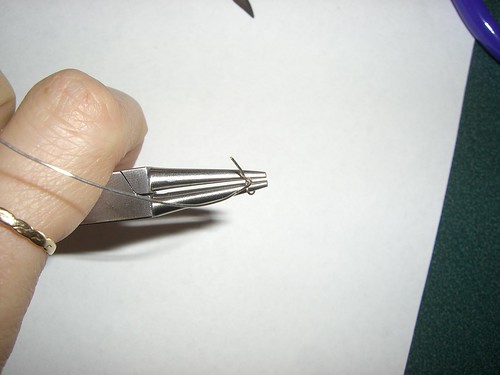

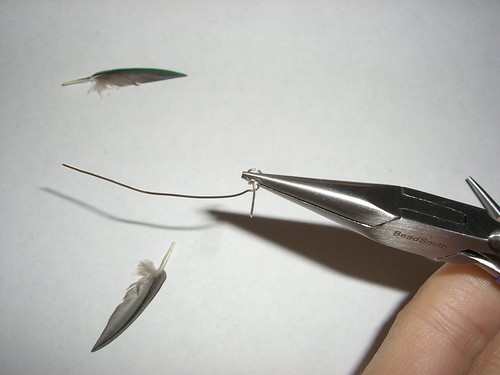

I checked to make sure I still had the right length of wire to hold next to the shaft, and finally cut the long wire free of the spool, so I had about 2 inches of wire to wrap -around- the shaft and short end.

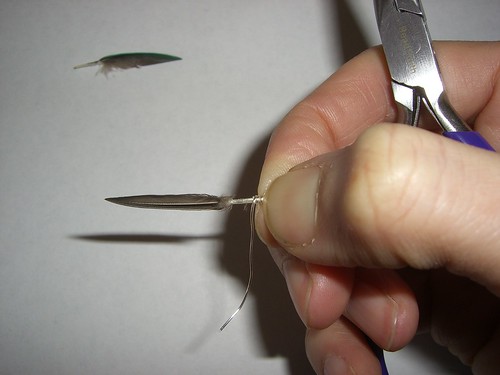

Why you should not use a tiny feather: Because holding the thin wire and the thin shaft together tightly while also wrapping thin wire AROUND them both is a pain in the butt. Holding the short wire and the shaft really tightly with pliers helped some (yes, it squashed the shaft. in fact I think it broke it a bit. it doesn't matter; you can't see it when you're done).

See that tiny loop of wire wrapped around the straight wire? Adjust that slightly if necessary so that it is just big enough to hold the very end of the feather shaft. That helps with the final wrapping.

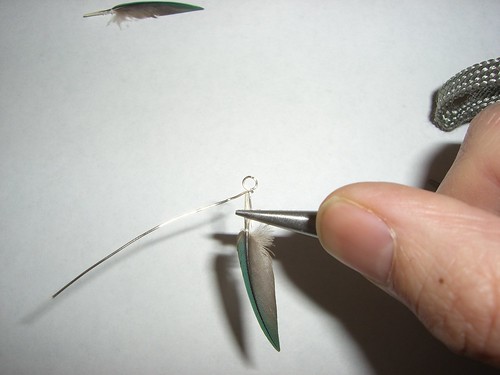

Another view of the loop

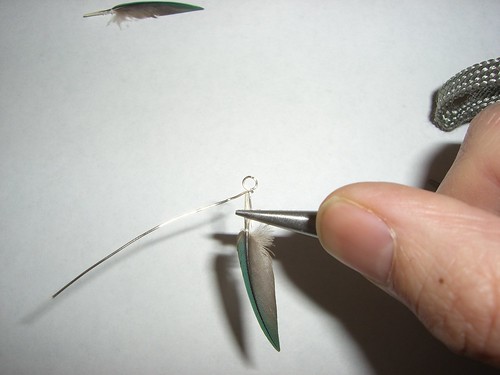

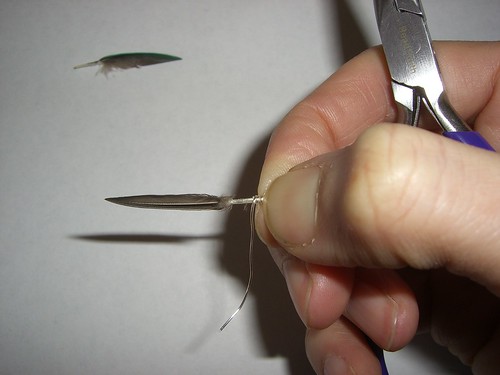

I gave up on the pliers because I couldn't get coordinated enough to manage and just pinched the feather+wire together tightly with my fingers. Having fingernails helps. Once I had the short piece of wire and the feather closely aligned, and the shaft of the feather just butting against the loop, I wrapped the long piece of wire around and around the shaft+wire combo.

Connect the feather to an earring loop, and you are done!

Thus endeth the lesson.

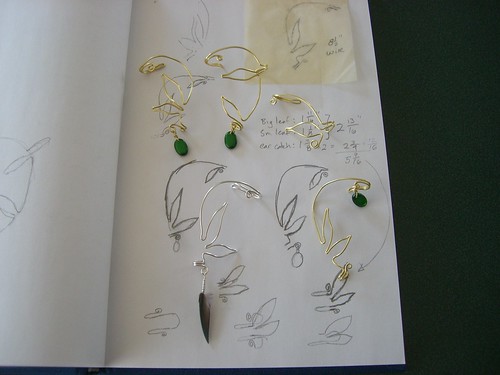

I didn’t keep the above earring; that’s just for photographic purposes. I wrapped another tiny feather and made these:

Feather and labradorite earrings. I have some tiny beads made from labradorite; in the right light, they show a blue "flash" that matches the feathers.

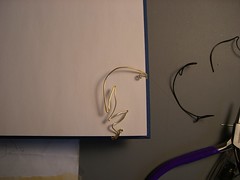

I also made an earcuff with a feather dangle, but those photos will be another post, because I have several other earcuffs I want to post at the same time.

Here is method 2 for wire wrapping a feather, but I didn’t like the results as well:

This time, I started wrapping near the fluffy part of the feather, not at the end of the shaft. I didn't want to wrap the entire bare shaft, because it was fairly long. I still wanted about half an inch of overlap between wire and feather, so I formed a loop about that far from one end of the wire (which I cut this time before starting! I CAN HAS LEARNINGS). This loop is not for hanging the feather, it will go around the shaft about half an inch from the end.

Forming the first loop

I placed the loop in the right position against the feather.

Another view of the wire and feather held together

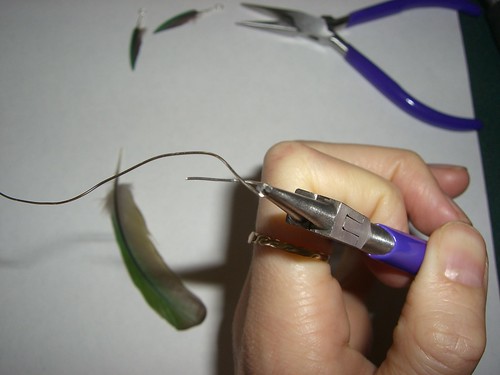

I again found it easier to start wrapping by holding the thing in my fingers. Here I have wrapped the wire around the feather+short wire once.

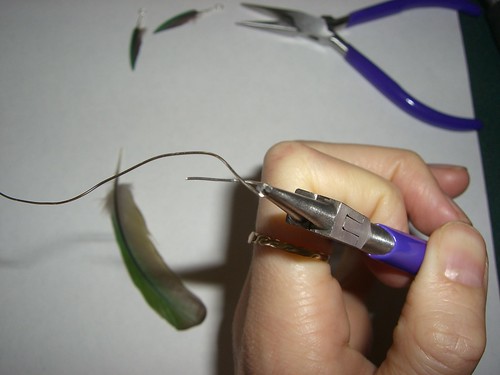

With the larger feather, and more shaft to work with, this time I found it easy to grab the wire and feather with the flat-nose pliers, and wrap the remaining wire around by hand. Part of the trick is that the wire is thinner than the feather shaft, so to hold both together, you really have to squash the feather. Otherwise, that dang wire will slide all over the place.

Don't worry about how the short wire is not tight against the shaft. As you wrap the long wire around them both, it will pull the shaft and short wire together. You will need to move the pliers out of the way; by this point, you don't need a death grip on the assembly, so you can place them over the wrapped section and hold firmly, just not so firmly you flatten things out.

I didn't get the wire positioned quite where I wanted, as there is a short bit of it sticking past the shaft. That can be clipped off.

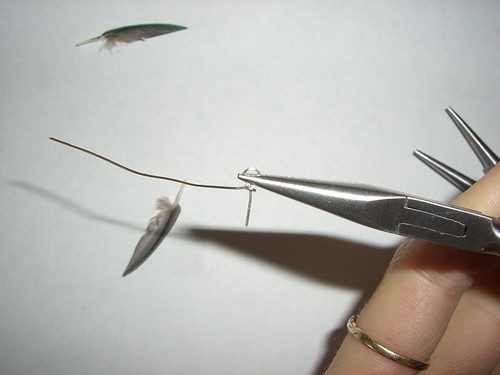

Now I have just enough wire left to make a loop to hang the feather from. I'm not wrapping to the very end of the shaft right now, because I will finish that after making the hanging loop.

I straightened out the wire so that it will be easier to wrap part of it against the shaft after I make the loop.

I used the round-nose pliers to make a loop at the end of the shaft. The bare bit of the shaft end, and the wire next to it, will be wrapped with the remaining wire.

I grabbed the loop with the flat-nose pliers, and wrapped the remaining wire back down the shaft, trapping the straight wire against it.

Finished!

* Some asides about pliers: Really, you could do this all with a single pair of needle-nose pliers, the kind you get at a hardware store. You won’t be able to get perfectly round loops, but if you don’t mind the look of a square-ish loop, go for it (I don’t have photos of this). You could also form the loop by wrapping the wire around a thin stick, like a bamboo skewer; the pliers just help hold the wire still while you wrap it. Also: most pliers not intended for jewelery-making have ridges/serrations on their jaws. These will mar the wire, which is a look you might like, but if not, wrap some tape (electrical, duct, whatever) around the serrated parts to protect the wire.